Numerical control equipment and metal stamping parts

2. Telecommunications Way Coverage - Core Accuracy Protection

This is one of the most technologically advanced stamping components in CNC machine tools. The precision guide rails and screw rods of machine tools are most afraid of iron filings and dust.

Stainless steel telescopic cover:

Function: As the workbench moves, the cover extends and retracts like an accordion, always covering above the guide rail to prevent iron filings from falling and jamming the guide rail.

Craftsmanship: Made by stamping and bending multiple high-quality stainless steel plates (usually SUS304).

Key point: Each section of steel plate must be extremely flat and equipped with stamped wipers to scrape off coolant and debris during expansion and contraction.

3. Chip Conveyor&Coolant - Digestive System

Numerical control machining generates a large amount of waste, which needs to be automatically discharged.

Hinged Belt Conveyor:

Chain Plates: The metal plates that are fastened together on the conveyor belt are typical stamped parts. They have protrusions on the surface (to prevent iron filings from sticking together) and are mass-produced through molds.

Water tank: A large box at the bottom that holds cutting fluid and is a thick plate stamping and welding component.

Filter water tank:

The internal porous filter is a dense perforated plate punched out by a CNC punching machine.

4. Electrical Cabinet - the house of the central nervous system

Behind the CNC machine tool, there is a huge electrical cabinet loaded with servo drives, frequency converters, and PLCs.

Cabinet structure:

Function: Achieve IP54 or higher protection level, prevent oil mist and dust from entering and damaging the circuit board, while shielding electromagnetic interference.

Process: Stamping and bending of galvanized sheet metal.

Install the base plate:

The thick galvanized sheet inside the cabinet where all components are installed.

Fan hood and filter set:

Stamped metal mesh cover, used for heat dissipation and ventilation.

5. Internal Brackets

The machine tool is filled with various pipelines and sensors inside.

Drag chain bracket: a metal slot that supports a plastic drag chain (with cables inside).

Travel switch collision block:

Function: A metal block that triggers an emergency stop when the machine tool moves to its limit position.

Process: Thick steel plate stamping with high positional accuracy requirements.

Motor cover/fan cover: a metal heat dissipation cover at the rear of the spindle motor.

6. Tool Magazine Parts

Stamping parts are also present in automatic tool changing systems.

Knife cover retaining spring:

Function: Clamp the handle of the knife in the magazine to prevent it from falling off.

Process: Spring steel stamping heat treatment, requiring extremely high fatigue life.

Knife changing robotic arm sheet metal: decoration and protective cover plate on the outside of the robotic arm.

Why can't CNC equipment do without stamping/sheet metal?

Functional protection: The CNC machining environment is extremely harsh (oil stains, iron filings, cooling water). Only metal stamping parts (especially steel plates and stainless steel after spraying) can withstand this long-term physical impact and chemical corrosion.

Customization and flexibility: There are numerous models of CNC machine tools available. Sheet metal stamping technology (especially CNC punching and laser cutting) can quickly produce different sizes of shells and covers without expensive molds, adapting to the production mode of multiple varieties and small batches.

Enhancing product value: Whether a machine tool is expensive or not, the first thing that catches the eye is sheet metal workmanship. The stamping shell with uniform gaps, smooth paint surface, and modern design can significantly enhance the level of the machine tool.

summary

In the CNC equipment industry, if the casting bed is the "skeleton" and the CNC system is the "brain", then metal stamping parts are the "skin" and "clothes".

It is not only responsible for wrapping the machine tool beautifully, but also bears the important responsibility of isolating danger, recycling waste, and protecting core accuracy. Without a high-quality stamping protection system, even the most sophisticated machine tools can be paralyzed within a few days due to the intrusion of iron filings.

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

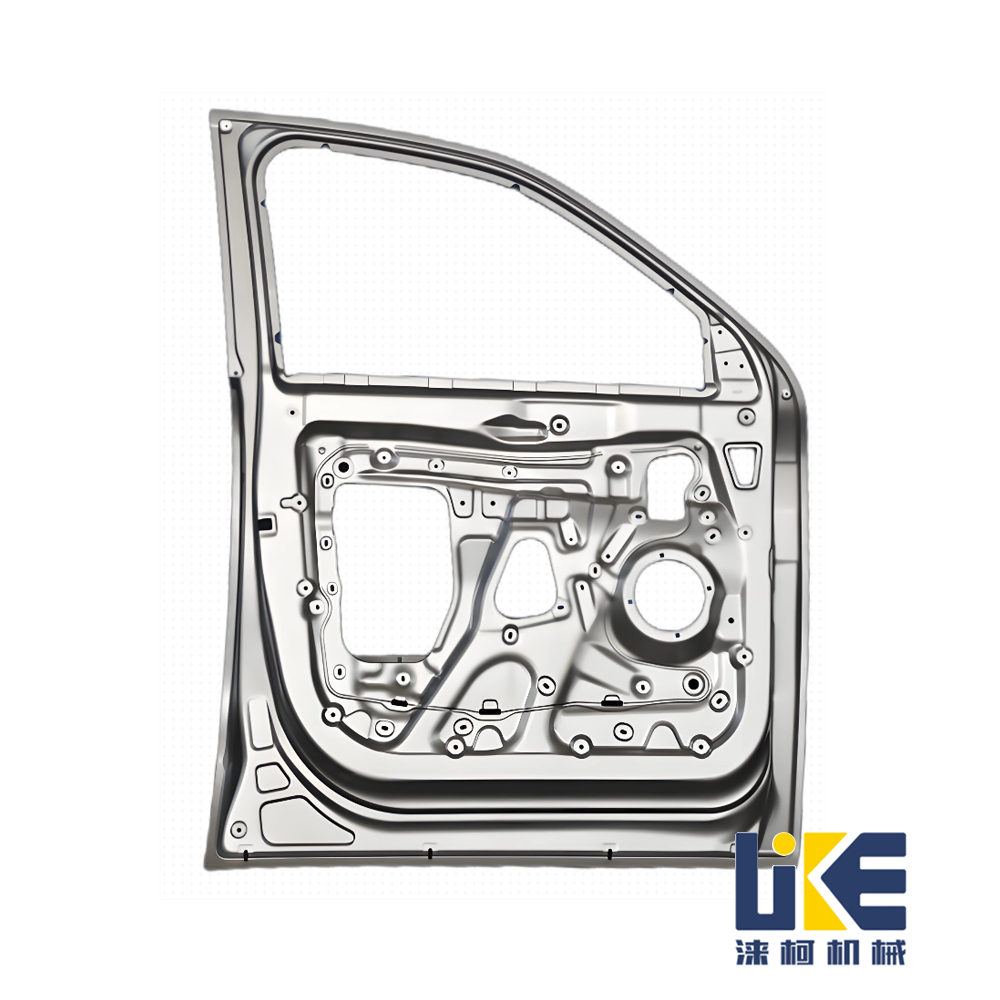

Automotive and metal stamping parts

Automotive and metal stamping parts

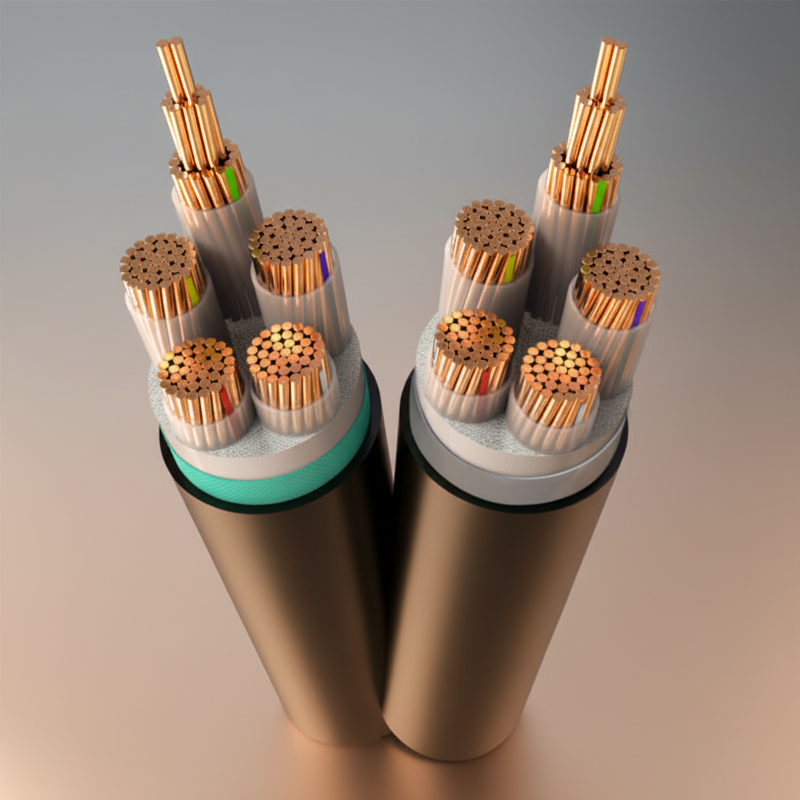

Cables and metal stamping parts

Cables and metal stamping parts

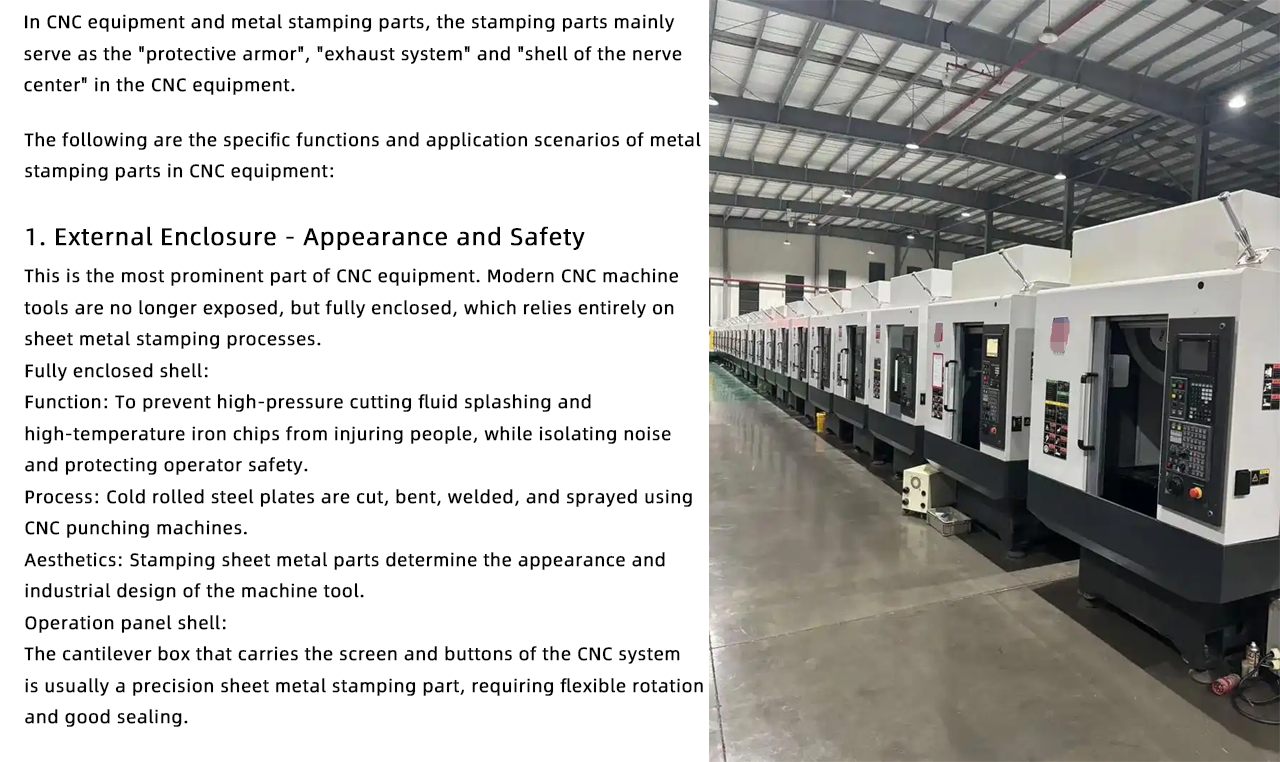

Numerical control equipment and metal stamping parts

Numerical control equipment and metal stamping parts